Exactly How to Identify Usual Repair Work Issues in Stretch Wrap Machines and When to Look For Specialist Help

Stretch Wrap makers are crucial for effective product packaging operations. They can experience various concerns that impede efficiency. Operators needs to be watchful in identifying signs of breakdown, such as irregular movie stress or unusual noises. Recognizing these typical repair service issues is vital. Yet, recognizing when to look for professional assistance can make a significant distinction. The subtleties of troubleshooting and upkeep deserve discovering even more.

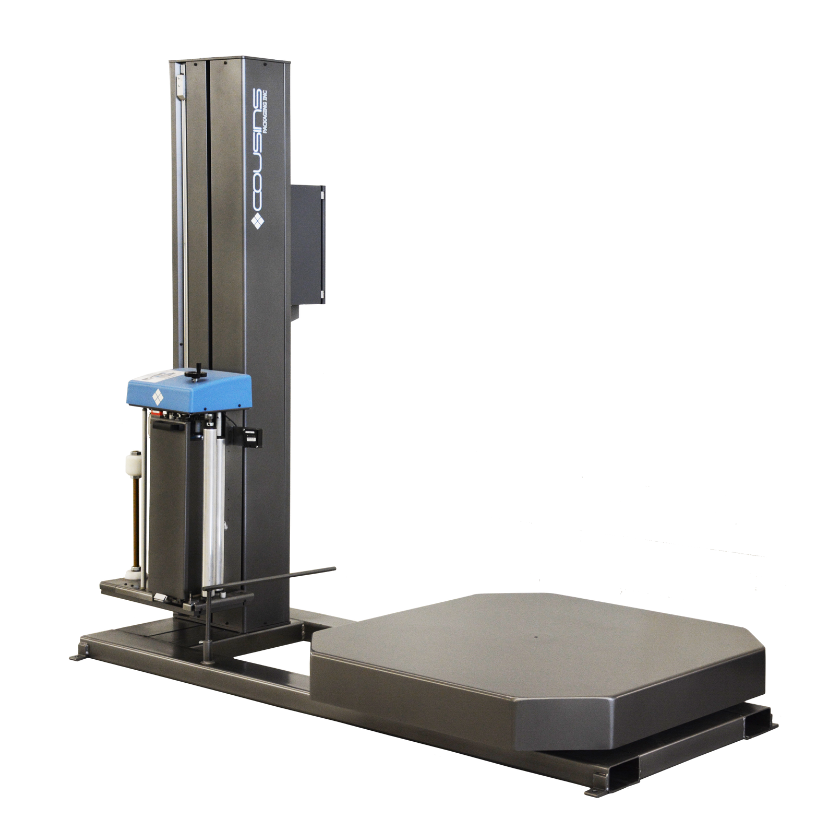

Understanding the Fundamentals of Stretch Wrap Machines

Stretch Wrap devices are essential tools in the packaging industry, created to securely encapsulate items for storage and transport. These devices make use of stretch film, which complies with itself, creating a protective and limited layer around things. Usually, they can be found in various types, including manual, semi-automatic, and completely automated models, providing to diverse production needs. The operation of a stretch Wrap machine entails feeding the movie around the product, applying tension, and securing the Wrap, making certain that products continue to be steady during transit.Key parts of these equipments consist of the movie carriage, turntable, and control panel, each playing a vital duty in the covering process. Performance is further boosted by adjustable setups that enable users to personalize the tension and number of covers. Understanding these essentials assists operators take full advantage of the maker's performance, making sure excellent packaging high quality and minimizing the danger of product damage throughout handling or delivery.

Usual Concerns With Stretch Wrap Machines

Product packaging performance can be considerably endangered by usual concerns that occur with stretch Wrap devices. One prevalent trouble is inconsistent film tension, which can lead to inadequate tons stabilization and boosted product damage throughout transportation. Additionally, movie damage commonly takes place, interfering with the wrapping process and triggering delays in operations. One more issue is the inappropriate alignment of rolls, which can result in unequal covering and waste of materials.Malfunctions in the control panel may additionally hinder functionality, making it hard to check or adjust setups efficiency. Electric problems, such as faulty electrical wiring, can even more add to operational inefficiencies. Normal upkeep can aid alleviate a lot of these troubles, ensuring the machine operates smoothly. Recognizing these usual concerns is essential for drivers, as prompt intervention can stop extra pricey repairs and considerable malfunctions.

Signs Your Stretch Wrap Machine Needs Repair Service

When a stretch Wrap machine displays uncommon noises during procedure, it may suggest underlying mechanical concerns. Additionally, inconsistent film tension and constant downtime can further signify that the equipment calls for immediate attention. Acknowledging these indications early can aid avoid expensive repair services and ensure peak efficiency.

Unusual Noises Throughout Operation

Unusual noises during operation typically signal underlying concerns with stretch Wrap machines that need prompt interest. These sounds might include grinding, squeaking, or clanking, which can indicate wear and tear on elements such as electric motors, equipments, or bearings. If the equipment creates unforeseen sounds, it may be battling with imbalance or not enough lubrication. Disregarding these audio cues can bring about more damages and costly repair services. Operators needs to conduct regular inspections to recognize and attend to the resource of the noise quickly. Consulting the device's handbook can provide details standards for upkeep and troubleshooting. If the issue persists after standard checks, seeking specialist help is suggested to ensure the equipment's longevity and height efficiency.

Inconsistent Film Stress

Inconsistent film tension can significantly impact the performance of stretch Wrap makers, causing substandard load security and prospective item damages. This issue often shows up as uneven covers, where particular locations of the tons are firmly safeguarded while others are loose. Operators may see that the stretch film is either under-stretched or over-stretched, impacting its capacity to adapt the load. In addition, there may be visible signs of shifting or slippage during transport, suggesting that the film is not supplying sufficient support. Such incongruities can result from damaged components, improper calibration, or malfunctioning sensing units. Addressing these issues without delay is vital to assure peak equipment efficiency and to avoid additional difficulties that could occur from insufficient wrapping.

Constant Downtime Issues

Constant downtime problems can signal that a stretch Wrap machine requires urgent repair service. These interruptions often suggest underlying mechanical failings or system breakdowns. Operators might discover enhanced frequency of jams, which interfere with the wrapping process and impede efficiency. Unusual noises throughout operation can also act as warnings, recommending that elements may be misaligned or worn out. Additionally, irregular movie application can cause inadequate load protection, triggering further operational delays. Disregarding these symptoms might cause a lot more serious damage and costly repair work. As a result, it is vital for drivers to monitor their makers very closely and address any type of indicators of breakdown without delay, guaranteeing effective operation and lessening downtime over time. Looking for professional help may be necessary for complex problems.

Troubleshooting Minor Problems

Repairing minor issues in stretch Wrap equipments calls for an organized technique to recognize and deal with concerns successfully. Operators needs to start here are the findings by examining the power supply and ensuring all links are safe and secure. If the device does not begin, verifying the circuit breakers and integrates can typically reveal simple electrical issues. stretch wrap machine repair near me.Next, inspecting the stretch Wrap film for correct positioning is vital. Misalignment can lead to irregular covering and may need change of the film rolls. Furthermore, drivers should monitor the tension setups; inaccurate tension check that may result in poor Wrap quality.Routine upkeep, such as cleaning up the rollers and ensuring they are without debris, can also protect against minor troubles from intensifying. Ultimately, keeping an eye on the machine's efficiency can help in recognizing patterns that suggest underlying concerns. By addressing these tiny worries promptly, operators can maintain peak capability and prevent bigger break downs

When to Hire a Professional

Operators might locate themselves faced with concerns that prolong past small modifications and regular upkeep. In such situations, identifying the ideal minute to contact a specialist ends up being vital. It might indicate a deeper electrical or mechanical mistake if the stretch Wrap machine continually fails to run appropriately regardless of troubleshooting efforts. In addition, uncommon sounds, consistent error messages, or failure to Wrap loads safely are signs that competence is needed.Furthermore, if the machine experiences constant malfunctions or if components are harmed, a professional's intervention is essential to stop additional problems. When unfamiliar with specific repair techniques or when safety threats are existing, Operators must also consider getting assistance. Eventually, timely specialist support can not only settle complex problems however likewise avoid pricey downtime and warranty top efficiency of the stretch Wrap maker.

Preventative Maintenance Tips for Stretch Wrap Machines

Regularly Asked Inquiries

What Is the Average Life Expectancy of a Stretch Wrap Machine?

Can I Use Various Types of Stretch Movie on My Machine?

Different kinds of stretch film can be made use of on an equipment, however compatibility and performance may differ - stretch wrap machine repair near me. It's essential to consult the equipment specifications and maker guidelines to ensure the finest results and protect against possible issues

Exactly How Can I Boost the Efficiency of My Stretch Wrap Device?

To boost stretch Wrap machine efficiency, routine maintenance, suitable film tension settings, correct placement, and employee training are essential. Furthermore, minimizing and updating components downtime via efficient operations can greatly boost general efficiency and outcome.

Exist Any Certain Brands Recognized for Integrity?

Several brand names are recognized for their reliability in stretch Wrap devices, consisting of Signode, Lantech, and Aetna. Individuals typically praise these makers for their resilience, performance consistency, and solid consumer assistance, boosting overall functional effectiveness.

What Is the Expense Range for Professional Fixes on Stretch Wrap Machines?

The expense variety for professional repair work on stretch Wrap devices varies considerably, generally between $150 to $1,500, relying on the intricacy of the issue, parts required, and the technician's competence included in the repair procedure. The operation of a stretch Wrap machine entails feeding the film around the product, using tension, and securing the Wrap, guaranteeing that goods stay stable throughout transit.Key components of these makers consist of the movie control, turntable, and carriage panel, each playing an important duty in the wrapping procedure. Inconsistent film stress can substantially affect the effectiveness of stretch Wrap makers, leading to substandard lots security and potential item damages. Regular downtime issues can indicate that a stretch Wrap equipment requires immediate repair work. The typical lifespan of a stretch Wrap maker normally varies from 5 to 15 years, depending on usage, upkeep, and the quality of the maker. To boost stretch Wrap device performance, regular upkeep, suitable film stress settings, proper alignment, and employee training are important.